Some Known Facts About Lean Production.s

Wiki Article

Lean Manufacturing - An Overview

Table of ContentsThe Single Strategy To Use For Manufacturing IndustriesSee This Report about Additive ManufacturingMfg Can Be Fun For Everyone9 Simple Techniques For Lean ProductionSome Known Factual Statements About Hon Hai Precision The Mfg PDFs

The message on this page is an example from our full White Paper 'Shot Moulding for Buyers' - * Sample text * - for full overview click the download button over! Introduction This overview is intended for people that are aiming to resource plastic mouldings. It offers a much needed understanding into all that is entailed with creating plastic parts, from the mould tool called for to the moulding procedure itself.If you want to check out even more, the guide covers types of mould tools, as well as special completing processes such as colours & plating. Words that are highlighted can be discovered in the reference in the appendix ... Part I: Moulding: The Fundamentals The Benefits of Injection Moulding Plastic shot moulding is an extremely exact procedure that offers numerous benefits over other plastic handling methods.

Accuracy is best for very complex components. Contrasted to various other methods, moulding allows you to incorporate more attributes at extremely small tolerances. Have an appearance at the picture to the right. lean manufacturing. You can hold this moulding in the hand of your hand and it has bosses, ribs, steel inserts, side cores as well as holes, made with a gliding shut off feature in the mould tool.

What Does Manufacturing Do?

from material feed & melting; material injection; cooling down time as well as ejection to the re-closing of the mould device ready for the following cycle. Draft angles - The wall surfaces of a moulded component should be a little tapered in the instructions in which the component is expelled from the mould tool, to enable the component to be ejected easily.

Ejector stroke - The pressing out of ejector pins to eject the moulded part from the mould tool. Ejector stroke rate, length and timing needs to be very carefully regulated to stop damages to the ejectors and mould device, yet at the same time make the moulding cycle as brief as possible.

Not known Facts About Oem

Ribs - When a plastic component has slim walls, ribs are included in the style to make the thin walls more powerful Side cores - Side action which creates an attribute on a moulded component, at an opposing angle to the normal opening instructions of the mould tool. manufacturing. The side core requires to be able to pull back as the plastic part can not be expelled or else.

Wall surfaces - The sides of a moulded component The text on this page is an example from our full White Paper 'Injection Moulding for Customers'.

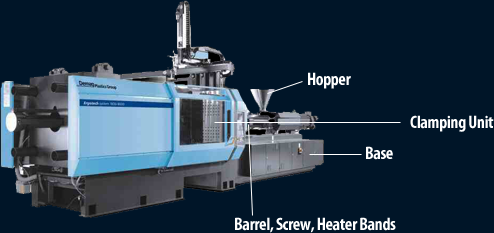

Manufacturing procedure for generating parts by infusing molten product right into a mould, or mold Simplified diagram of the procedure Injection moulding (U.S. spelling: shot pcb prototype molding) is a manufacturing procedure for generating components by injecting molten product into a mould, or mold and mildew. Shot moulding can be carried out with a host of materials mostly including steels (for which the procedure is called die-casting), glasses, elastomers, confections, as well as many typically polycarbonate and also thermosetting polymers. Shot moulding is commonly made use of for manufacturing a selection of parts, from the tiniest components to entire body panels of automobiles. Injection moulding utilizes a special-purpose machine that has three components: the injection device, the mould as well as the clamp.

Additive Manufacturing Things To Know Before You Get This

Process attributes [modify] Injection moulding utilizes a ram or screw-type bettor to force molten plastic or rubber product into a mould cavity; this solidifies into a form that has satisfied the contour of the mould. It is most commonly utilized to process both thermoplastic and also thermosetting polymers, with the quantity use the previous being considerably higher.: 13 Thermoplastics prevail as a result of features that make them highly suitable for shot moulding, such as ease of recycling, convenience for a wide array of applications,: 89 and ability to soften as well as stream on heating.In multiple tooth cavity moulds, each cavity can be similar and form the very same components or can be unique as well as create multiple different geometries throughout a single cycle. Moulds are generally made from tool steels, however stainless steels as well as aluminium moulds are appropriate for particular applications. Aluminium moulds are usually improper for high volume production or parts with narrow dimensional tolerances, as they have inferior mechanical buildings and are extra susceptible to put on, damage, as well as contortion throughout the injection and clamping cycles; nonetheless, aluminium moulds are cost-effective in low-volume applications, as mould construction prices and time are substantially decreased.

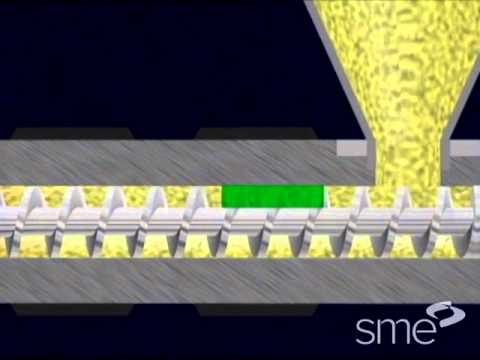

The screw provides the raw material ahead, mixes and also homogenises the thermal as well as thick circulations of the polymer, and decreases the called for heating time by mechanically shearing the product and including a significant amount of frictional heating to the polymer. The product feeds ahead via a check shutoff and also accumulates at the front of the screw into a quantity known as a shot. When enough product has actually gathered, the product is forced at high pressure and also velocity right into the part creating dental caries. The exact amount of shrinkage is a function of the resin being used, as well as can be reasonably predictable. To stop spikes in pressure, the procedure usually uses a transfer position representing a 9598% complete cavity where the screw changes from a consistent velocity to a continuous stress control.

The Main Principles Of Manufacturing

The packing stress is used until the entrance (tooth cavity entrance) strengthens. Due to its tiny dimension, the gateway is typically the very first area to strengthen via its entire thickness.: 16 Once the gateway strengthens, no more product can get in the cavity; accordingly, the screw reciprocates as well as obtains material learn this here now for the next cycle while the product within the mould cools so that it can be ejected and also websites be dimensionally stable.Report this wiki page